my 900 is shredding my belts like no tomorrow does anybody have a solution for that

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Help with 2006 900 rmk

- Thread starter ruskiDOitBEST

- Start date

If you want to stop blowing belts you have to do a few things.

Add vents. Lots of vents.

Run the polaris 115 belt.

Gear down.

Slp torque stop arms.

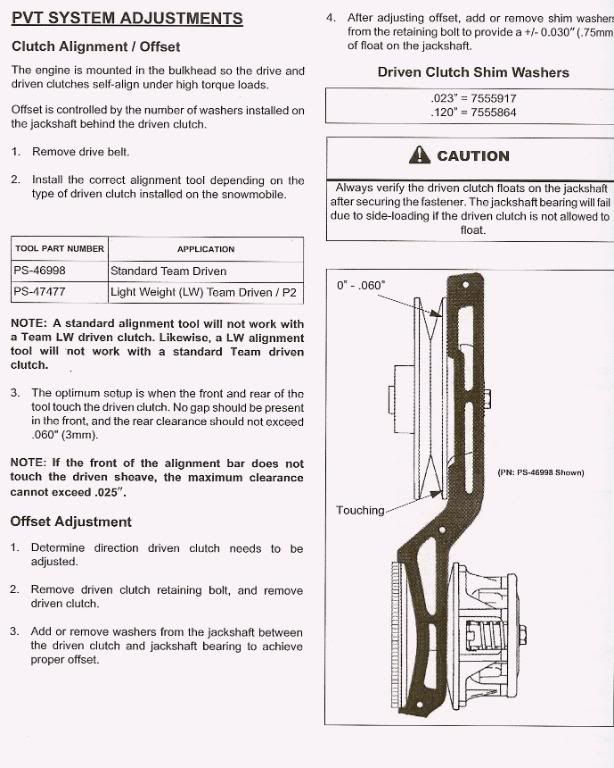

Float the secondary.

Make sure your motor mounts are not broken.

There is more you can do but this should help alot.

Add vents. Lots of vents.

Run the polaris 115 belt.

Gear down.

Slp torque stop arms.

Float the secondary.

Make sure your motor mounts are not broken.

There is more you can do but this should help alot.

my 900 is shredding my belts like no tomorrow does anybody have a solution for that

You need new motor mounts. There is no adjustment for the clutch alignment built for the 900 RMK. It's either on or off.

PM CompFusion on here and put a set of his motor mounts in ... then put a 66/44-42ER helix and 19/42 gears in it and your problems will be solved ... and it will run better to boot.

ditto on the compfusion mounts that fixes the belt issues with this sled and you dont need the torque arm or push arm from slp as those are just a cheap bandaid fixes for the worthless stock motor mounts, my stock front pto side mount had a tear 1/2 way through it.... hope this helps.

Are the compfusion mounts harder or softer? how do they effect the vibration of the sled??

Thanks,

Nolan

Thanks,

Nolan

E

Ex-Member

ACCOUNT CLOSED

Yeap, motor mounts, torque arm, or clutch alignment.

Gearing down will reduce belt heat, which prolongs belt life. Venting helps too, but I just have the one small-ish vent in the side panel and I only blew one belt, the second day I had the sled. No idea what the previous owner did to it, but I ran an 080 all last year and it worked fine. I'm now on a Gates Xtreme and it's doing well (Half the price of the 080's too).

Gearing down will reduce belt heat, which prolongs belt life. Venting helps too, but I just have the one small-ish vent in the side panel and I only blew one belt, the second day I had the sled. No idea what the previous owner did to it, but I ran an 080 all last year and it worked fine. I'm now on a Gates Xtreme and it's doing well (Half the price of the 080's too).

K

krat

Member

Are the compfusion mounts harder or softer? how do they effect the vibration of the sled??

Thanks,

Nolan

Supposed to be harder. I don't know if they transmit more vibration to the chassis.

see this thread

where can i order these parts? my mtor mounts are new they swaped them this winter

Factory torque stop

My factory torque stop was way out of Polaris spec's as well. Located behind the primary clutch. Dealer cranked that stop down so its nearly touching the engine plus I had them install the SLP torque stop and arm. Also switched belts to the 3211115 and put shock tower vents in. Best thing was vent it and gear it down. Now I can at least touch the belt after a climb.

i had the same problem, my mounts were still good and my torque arm was waaaay out(says the dealer) like a cm of play. never blew a belt after that(about 400miles), but the sled is long gone now

My factory torque stop was way out of Polaris spec's as well. Located behind the primary clutch. Dealer cranked that stop down so its nearly touching the engine plus I had them install the SLP torque stop and arm. Also switched belts to the 3211115 and put shock tower vents in. Best thing was vent it and gear it down. Now I can at least touch the belt after a climb.

C

CompFusion

Well-known member

Are the compfusion mounts harder or softer? how do they effect the vibration of the sled??

Thanks,

Nolan

The urethane isolating material used in my kit is, in fact, the same 60 durometer hardness as the OEM mounts. It does indeed hold the engine in place better but it is from the way it does it as opposed to the hardness of material. I've had guys report a worse vibration and more report a reduction. IMHO I think it depends on setup of each sled and the imbalance of the rotating assembly. Guys that have never had the primary balanced and/or use rigid torque arms seem to have more vibes. For vibration reduction look into checking crankshaft run-out and balancing the primary clutch.

G

ghostwhite

Well-known member

ttt

Similar threads

G

- Replies

- 0

- Views

- 115

G